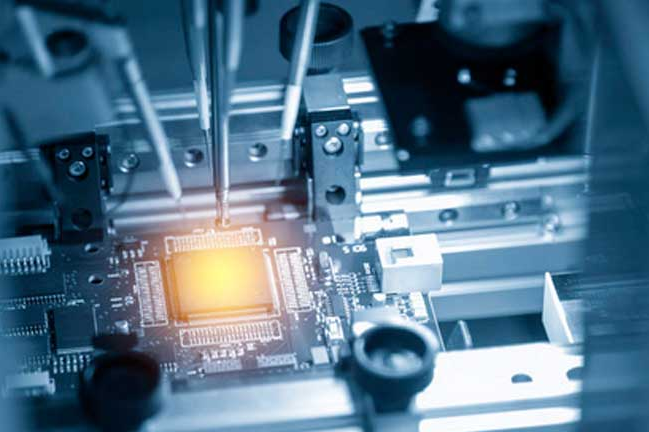

As an IC manufacturer, the most concerned issue is the product yield because the product is constantly updated and iterated on the market, many new products have very high requirements for the process. However, because the current production process is difficult to meet the corresponding standards, it will form a phenomenon that the product yield is very low. So is this product difficult to produce? What should I pay attention to?

First, the choice of raw materials for products

As an IC manufacturer, the most critical factor affecting the product yield is the quality of raw materials. Therefore, when choosing raw materials for products, we must pay attention to screening and select those products with good quality. In order to be able to find the problem in a timely manner, there must be a special person to choose when purchasing raw materials. Because the specialized personnel are very strict in the control of each process of the product and have certain early warning of possible problems, they are more experienced in the selection of raw materials.

Second, the control of the process

After determining the raw materials of the product, the reproduction process, the most important thing is the control of the process, for IC manufacturers, the process needs to be carried out in strict accordance with the relevant standards, if there is a problem, it will affect the product yield, resulting in the entire product can not pass the inspection.

Third, the packaging of the product

The packaging of the product has a relatively small impact on the product, but it is also a link that can not be ignored. The packaging of the product needs to be carefully designed for IC manufacturers and choose durable packaging with good materials.

The production difficulty of IC manufacturers is relatively high, because the product has relatively high requirements for the process, so the control process of related problems is also relatively strict, and there are more problems that need attention.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA