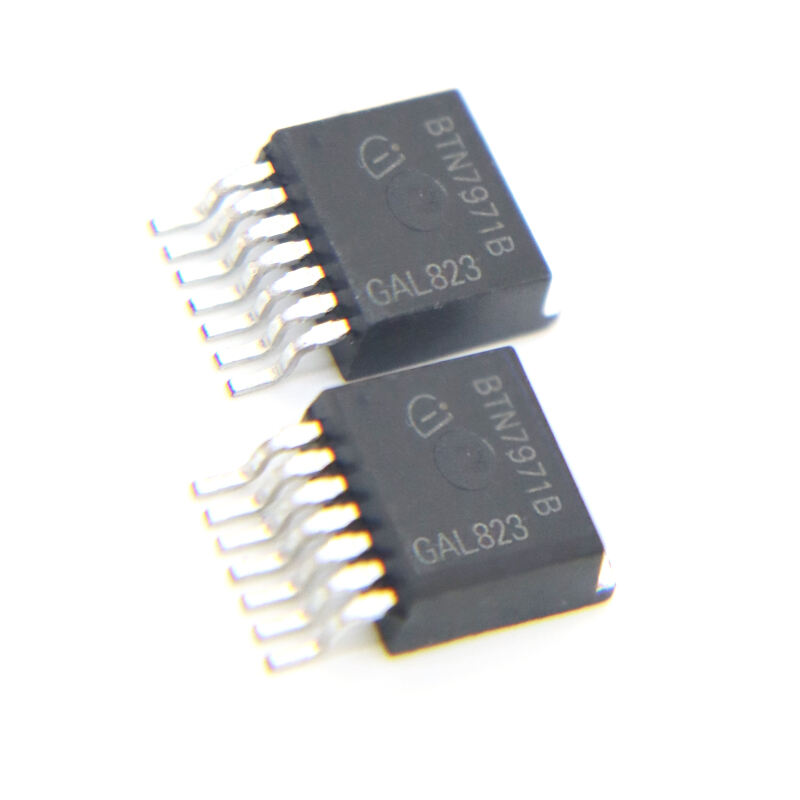

Stepper Motor Chip: Precise Motor Control With High-Quality Stepper Motor Ics

Stepper motors are the vital unit of construction in a number of spheres where the movement ability is required in detail. There are stepper motors used for such purposes which may be controlled with Stepper Motor Chip or its integrated circuit (IC) for precision and better performance. This article is intended to discuss stepper motor chip design issues with stress put on its strengths, construction, and application areas.

A stepper motor chip is a microchip that enables stepper motors to be controlled through digital instructions by sending electrical energy pulses which rotates the motor in definitive increments as determined by the pulse cycles. This is important in instances where there should be certain precision of the movement for example in positioning systems in robotics or CNC machining systems.

Microstepping in Stepper Motors

Modern-day stepper motor chips significantly stand out with their support for microstepping, which is an advanced functionality. This technology allows for further sections to be formed on each step of the motor allowing for seamless and intricate movements as it is a least vibration feature. Microstepping enhances control and diminishes vibrations ensuring that applications where accuracy is required such as 3D printing and layer deposition are done with accuracy and quality.

The current control system integrated within the chip

Regarding current control management, instruction step motor integrated circuits have many high functional options. These options govern the degree of electricity being supplied to the motor, thus preventing the copper motor from burning out while enhancing its efficiency. Having this feature built in will not only prolong the lifetime of the motor and the chip, but also the reliability of the entire system which is a core feature of every great design.

Connection to control units

The stepper motor chips have been made compatible with numerous control units including microcontrollers and programmable logic controllers (PLC). This feature promotes efficient interaction and thus enables smooth and complex motion control without much to additional circuits. Being able to communicate in various modes enables these chips to be applied in different works.

Widespread use in various industries

Many industries across the globe are making use of stepper motor chips. In the field of robotics, these chips make it possible for the robotic arm and specific machines to carry out movements that are very accurate. In 3D printing, because stepper motors enable even layer deposit that helps in achieving good quality prints, they are essential for fork oil application. Other uses are in medical means that require intricate functioning as well as in textile machines that require specific patterns of stitching.

To conclude, stepper motor drivers or steppers are a requisite for accurate control of the motors in different applications. It is the ability to support multi-stepping, self-contained current regulation, and simple circuitry that makes them indispensable in the current industry. If you are looking for superior and reliable stepper motor ICs, that would meet your specifications, you must contact [Keshijin]. Reach out to us now to help you in optimizing your projects with our state-of-the-art motor control systems!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA